https://pioneerair.com/wp-content/uploads/2024/05/A-Guide-to-Desiccant-Types-Applications-and-Lifespans.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/05/pioneer_air_systems_logo.png

Abstrakt Marketing2024-05-09 20:39:292026-02-26 20:27:47A Guide to Desiccant Types, Applications, and Lifespans

https://pioneerair.com/wp-content/uploads/2024/05/A-Guide-to-Desiccant-Types-Applications-and-Lifespans.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/05/pioneer_air_systems_logo.png

Abstrakt Marketing2024-05-09 20:39:292026-02-26 20:27:47A Guide to Desiccant Types, Applications, and LifespansA Guide to Desiccant Types, Applications, and Lifespans

If you’re in an industry that grapples with moisture control, you’re likely familiar with desiccants, but what exactly are they? In this blog, we will break down desiccants, shine a light on their critical role in moisture absorption and unpack the science that makes them indispensable. Understand how desiccantscater to different needs across various industries, and learn the key factors that affect desiccant lifespan.

What Are Desiccants?

Desiccants may not be a topic of everyday conversation, but they play an indispensable role in protecting a vast array of products from the detrimental effects of moisture. Simply put, desiccants are materials designed to absorb and hold onto moisture from their environment. By doing so, they ensure that humidity-sensitive goods remain dry and pristine during storage and transport, thus prolonging their life and maintaining their quality.

Common Varieties of Desiccants

The world of desiccants is as varied as the industries that rely on these moisture-wicking champions. Here are some of the most common desiccant types:

- Silica Gel: Renowned for its efficacy, this porous form of silicon dioxide is able to absorb a significant amount of water, thanks to its large internal surface area.

- Activated Alumina: Synthetic and highly porous, this desiccant excels at removing water from gases and liquids without changing its form.

- Calcium Chloride: A robust desiccant, calcium chloride is able to attract moisture aggressively and is often used in road deicing and brine refrigeration systems.

- Molecular Sieves: These synthetic crystalline zeolites perform with high precision, trapping water molecules in their uniform pores, which allows for selective absorption.

- Clay: A naturally occurring and economical option, clay desiccants are often used for their reliability and effectiveness in standard humidity control applications.

Each type of desiccant has its own profile of characteristics, making them suitable for particular tasks and environmental conditions. Understanding their distinct properties is key when selecting the right desiccant for a specific purpose.

The Applications and Importance of Desiccants

From food packaging to industrial machinery, desiccants serve as the first line of defense in preserving the quality and extending the lifespan of countless products. Let’s check out the varying applications of desiccants and understand why they’re indispensable in various sectors.

Vital Applications in Moisture Management

The role of desiccants extends beyond the simple silica gel packets found in a new shoebox. They are essential in a variety of fields:

- Pharmaceuticals: Desiccants maintain low humidity levels in packaging, crucial for preserving the efficacy of medications.

- Electronics: Moisture-sensitive components and devices rely on desiccants to prevent corrosion, ensuring reliability and longevity.

- Food Industry: Food products are kept fresh and free from spoilage through the use of desiccants, safeguarding taste, texture, and nutrition.

- Shipping & Logistics: Desiccants protect goods from moisture damage during transit, particularly across drastic climate changes.

- Aerospace: High-performance desiccants are used to control the environment in critical aerospace systems and components.

The Importance of Desiccants in Quality Preservation

Using desiccants goes beyond convenience; it is a necessity for the assurance of product quality and integrity. The ability to control moisture plays a pivotal role in:

- Product Longevity: By preventing the deleterious effects of humidity, desiccants significantly extend the usable life of products.

- Safety: Some materials can become hazardous with too much moisture. Desiccants serve as a safeguard, protecting both products and consumers.

- Equipment Performance: Many industries employ desiccants to ensure the optimal functioning of machinery, guarding against moisture-induced failures.

- Material Preservation: From leather goods to metal parts, desiccants help maintain material properties by staving off oxidation and degradation.

The applications mentioned only scratch the surface of desiccants’ potential. With a clear understanding of their importance, it’s easier to appreciate why they are fundamental in so many aspects of modern industry.

Understanding the Factors That Influence Desiccant Longevity

Several key factors converge to play a role in how long your desiccant will last. Awareness of these variables can help you in making informed decisions to preserve your desiccants’ lifespan and ensure they continue to protect your products from the damaging effects of moisture.

Environmental Conditions

Environmental conditions are among the primary elements affecting desiccant longevity. Temperature, humidity levels, and even the presence of contaminants in the air can influence how a desiccant performs over time. High humidity and elevated temperatures can lead to a quicker saturation of desiccants, necessitating more frequent replacement or recharging.

Type of Desiccant

Not all desiccants are created equal. The type of desiccant used is a critical factor in determining its lifespan. Silica gel, activated clay, and molecular sieves, for example, each have unique properties and capacities for moisture absorption. Selecting the appropriate desiccant based on the specific requirements of the application is essential for optimal performance and longevity.

Level of Moisture Exposure

The level of moisture exposure is a direct determinant of how long a desiccant will remain effective. Desiccants used in environments with consistent exposure to moisture will reach their absorption capacity much quicker than those in less saturated conditions. Understanding and regulating the moisture levels in the storage or packaging environment is key to preserving a desiccant’s lifespan and ensuring it works as intended.

Looking for Long-Lasting Desiccants?

Pioneer Air Systems offers desiccantsthat are expertly curated to not only maintain fuel gas purity standards but also to offer superior control over pressure dew points. Whether you’re dealing with wet gas and air or you’re in need of point-of-use and regenerative drying solutions for industrial applications, we have the right desiccantsfor the job. Learn more below.

Recognizing the Signs: When Your Desiccant Needs Replacement

Ensuring that your desiccants are functioning optimally is crucial for maintaining the integrity of your moisture-sensitive products. But how can you identify when your desiccants are nearing the end of their lifespan? Let’s explore some tell-tale signs.

Visual Changes and Performance Indicators

Some desiccants offer visual cues that indicate saturation. For instance:

Color Change: Silica gel desiccants may contain moisture indicators that shift colors, such as from blue to pink, signaling that they have absorbed moisture to capacity.

Clumping: Desiccants, such as clay, might clump together when they’re no longer effective, a clear signal that it’s time for replacement.

Weight Increase

Weight Gain: A simple yet effective method to determine if a desiccant is spent is by weighing it. Desiccants gain weight as they absorb moisture. If a desiccant’s weight has significantly increased since its initial use, it may be reaching its maximum moisture capacity.

Reduced Efficacy

Assessing the condition of the protected goods can also serve as an indicator:

- If you notice condensation or corrosion that wasn’t present before, it might be due to a desiccant no longer effectively controlling humidity.

- Monitoring humidity levels within the storage or packaging area with a hygrometer can tell you if the desiccant is maintaining the desired dryness.

Expiration Date and Usage Duration

Lastly, if your desiccant comes with a manufacturer’s recommended shelf life or usage duration, be mindful of these timeframes. Surpassing the recommended period often means the desiccant is no longer performing at full capacity and requires replacement.

Maximize Your Desiccant’s Efficiency: Practical Lifespan Extension Tips

Ensuring your desiccants retain their ability to control moisture effectively is key to maintaining the integrity of your products and systems. The following practical tips will help you prolong the lifespan of your desiccants and guarantee peak performance.

Optimal Storage Solutions

Store desiccants in a cool, dry place to prevent premature degradation. Factors such as high temperature and humidity can reduce the efficacy of desiccants over time, thus storage conditions should be controlled to extend their usability.

Seal Your Success

Proper sealing techniques are essential for maximizing the lifespan of desiccants. Use air-tight containers or sealed bags to prevent exposure to ambient humidity. This simple step can substantially delay the saturation of desiccant materials.

Control the Environment, Control the Outcome

Whenever possible, maintain controlled environmental conditions to limit the challenges your desiccants face. For example, using dehumidifiers in storage areas can support the longevity of the desiccant by reducing the amount of moisture they need to absorb.

Tailored Approaches for Different Industries

Depending on the industry and application, desiccants might encounter a wide array of environmental stresses. In highly moist or volatile environments common in the shipping or chemical industries, it may be necessary to use desiccants with higher absorption capacities or to replace them more frequently.

Timely Replacement and Regeneration

Understanding when and how to replace or regenerate your desiccants is crucial for ongoing moisture control. Monitor the performance of your desiccants closely and establish maintenance schedules that reflect their varying usage demands and capacities.

Contact Pioneer Air Systems for High-Quality Desiccants

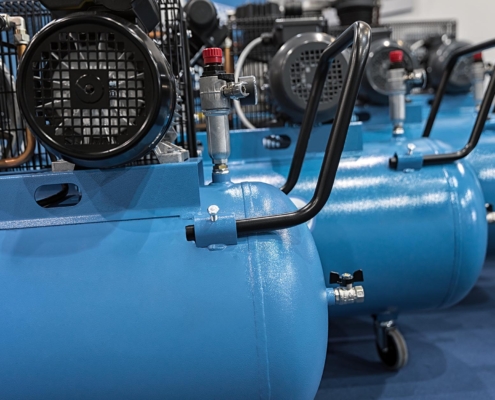

For over 40 years, Pioneer Air Systems has established itself as a premier manufacturer and supplier in the realm of compressed air system desiccants. Our commitment to quality and performance is evident in our selection of top-of-the-line air dryer desiccants, recognized for their reliability, cost-effectiveness, and energy efficiency. With a steadfast focus on providing solutions tailored to each client’s unique moisture removal needs, we ensure that your compressed air systems function at their highest potential.

Choose Pioneer Air Systems as your trusted desiccant supplier and benefit from our expertise in air moisture control to ensure the success and longevity of your compressed air dryer systems.