https://pioneerair.com/wp-content/uploads/2024/05/Choosing-Replacement-Desiccant-Air-Dryers-Pitfalls-to-Avoid.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/05/pioneer_air_systems_logo.png

Abstrakt Marketing2024-05-09 20:47:392025-12-27 20:32:17Choosing Replacement Desiccant Air Dryers: Pitfalls to Avoid

https://pioneerair.com/wp-content/uploads/2024/05/Choosing-Replacement-Desiccant-Air-Dryers-Pitfalls-to-Avoid.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/05/pioneer_air_systems_logo.png

Abstrakt Marketing2024-05-09 20:47:392025-12-27 20:32:17Choosing Replacement Desiccant Air Dryers: Pitfalls to AvoidChoosing Replacement Desiccant Air Dryers: Pitfalls to Avoid

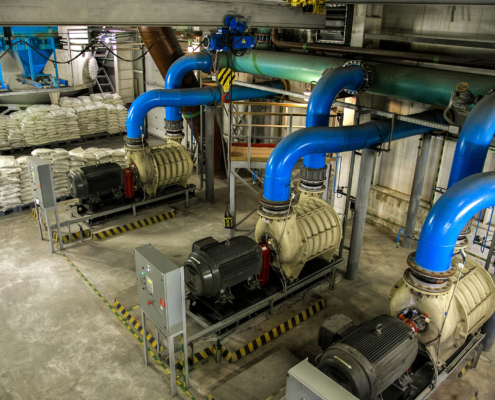

In industrial and commercial settings, maintaining optimal moisture control is paramount to ensuring process efficiency and equipment longevity. Desiccant air dryers play a crucial role in absorbing moisture from compressed air systems to prevent corrosion, equipment malfunction, and product spoilage. However, the effectiveness of these systems hinges on selecting the right replacement desiccants.

Understanding the Importance of Replacement

Effective moisture control is essential across a wide range of industries, including pharmaceuticals, food and beverage, electronics, and manufacturing. Moisture in compressed air systems can lead to corrosion, product degradation, and malfunctions in pneumatic equipment. Therefore, timely replacement of desiccants is crucial to maintaining optimal moisture levels and preventing these issues. Regular replacement ensures that desiccants absorb moisture efficiently, preserving the integrity of products and equipment.

Identifying Common Pitfalls

Choosing replacement desiccants without proper consideration can result in inefficiencies and operational disruptions. One common pitfall in selecting desiccants based solely on cost, without considering factors such as moisture absorption capacity and compatibility with the application. Another mistake is failing to ensure compliance with industry standards, which can lead to compromised quality and safety.

Underestimating moisture levels or selecting improper desiccant types can render the system ineffective. By understanding these pitfalls, businesses can make informed decisions and avoid potential issues.

Compatibility with Industry Standards

Compliance with industry standards and regulations is paramount to ensuring the quality and safety of replacement desiccants. Desiccants used in pharmaceuticals and food processing industries must meet stringent standards to prevent contamination and ensure product integrity. By verifying desiccants’ compliance with relevant quality and safety standards, businesses can mitigate risks and maintain regulatory compliance.

Environmental Considerations

Environmental conditions can significantly impact the performance of desiccants. Factors such as temperature, humidity, and exposure to chemicals can affect the efficiency of moisture absorption. For example, high humidity levels may require desiccants with higher moisture absorption capacities, while exposure to corrosive chemicals may necessitate chemically resistant desiccants. By selecting desiccants suitable for their specific operating environments, businesses can optimize moisture control and prevent potential issues arising from environmental factors.

Moisture Levels and Capacity

Matching the moisture absorption capacity of replacement desiccants with actual moisture levels is crucial for optimal performance. Calculating the application’s moisture load helps businesses determine the appropriate desiccant type and quantity needed to achieve the desired level of moisture control. By accurately assessing moisture levels and capacity requirements, businesses can prevent underperformance or overloading of desiccants, ensuring efficient moisture removal and equipment protection.

Storage and Shelf Life

Proper storage practices are essential to maintain the effectiveness of replacement desiccants. Desiccants should be stored in sealed containers or bags in a cool, dry place to prevent exposure to moisture and contaminants. Additionally, monitoring the shelf life of desiccants ensures that they remain effective and reliable. Regular inspections and inventory management help businesses identify expired or degraded desiccants and replace them promptly. By adhering to proper storage practices and monitoring shelf life, businesses can maximize the longevity and performance of replacement desiccants.

Regeneration Capabilities

Some desiccants offer regeneration capabilities, allowing them to be reused multiple times through heating or vacuum drying processes. This not only reduces waste but also provides a cost-effective solution for businesses. However, not all desiccants are suitable for regeneration, and the effectiveness of regeneration methods may vary depending on the desiccant type and application. By understanding the regeneration capabilities of different desiccants and evaluating their suitability for specific needs, businesses can make informed decisions to optimize cost-effectiveness and operational efficiency.

Cost Considerations

Balancing upfront costs with long-term value is essential when choosing replacement desiccants. While cost is important, businesses should also consider performance, reliability, and durability factors. Investing in high-quality desiccants may entail higher upfront costs but can lead to significant savings in the long run by reducing maintenance costs, downtime, and product losses.

Vendor Selection

Selecting reputable and reliable vendors is critical for obtaining high-quality replacement desiccants. Businesses should consider factors such as vendor reputation, product quality, customer reviews, and after-sales support when choosing a vendor. Additionally, verifying certifications and quality assurance processes helps ensure that desiccants meet industry standards and regulatory requirements.

Think it’s time for a replacement air dryer in your industrial facility? Check out the different types of desiccants we have available at Pioneer.

Understanding Desiccants: Types and Applications in Industrial Moisture Control

Desiccants are crucial in industrial moisture control, absorbing moisture from the air to prevent corrosion, contamination, and product spoilage. However, not all desiccants are created equal.

Silica Gel

Silica gel is perhaps the most well-known and widely used desiccant in industrial settings. It is composed of silicon dioxide and has a high moisture absorption capacity, making it ideal for general-purpose drying and packaging applications. Silica gel works by adsorbing moisture molecules onto its surface, effectively reducing the humidity level in the surrounding environment. Its versatility and effectiveness make it suitable for a wide range of industries, including pharmaceuticals, electronics, food packaging, and textiles.

Activated Alumina

Activated alumina is another popular desiccant commonly used in industrial applications, particularly in compressed air systems. It is made from aluminum oxide and has a highly porous structure that allows for the effective adsorption of water vapor and acidic contaminants. Activated alumina is particularly effective at removing moisture from compressed air, ensuring that downstream equipment remains dry and corrosion-free.

Molecular Sieve

Molecular sieve is a specialized type of desiccant with a uniform pore structure that allows for highly selective adsorption of moisture molecules. It is typically composed of zeolite minerals and is known for its exceptional moisture removal capabilities. Molecular sieve is commonly used in applications requiring stringent moisture control, such as natural gas drying, dehydration of solvents, and air separation processes. Its ability to selectively adsorb specific molecules makes it ideal for removing moisture from gases and liquids without affecting other components.

Choosing the Right Desiccant

Understanding the characteristics and applications of different desiccants is essential for choosing the right option for specific moisture control needs. Factors to consider include:

- Moisture Absorption Capacity: Different desiccants have varying moisture absorption capacities, so it is crucial to select a desiccant with sufficient capacity to meet the application’s moisture removal requirements.

- Operating Conditions: Operating conditions, such as temperature, humidity, and pressure, should be considered, as these factors can affect the performance of desiccants.

- Specific Applications: Certain desiccants may be better suited for specific applications based on their properties and performance characteristics. For example, silica gel may be suitable for general-purpose drying, while molecular sieve may be required for applications requiring high levels of moisture removal.

- Regeneration Capability: Some desiccants, such as activated alumina and molecular sieve, can be regenerated and reused multiple times, providing cost savings and sustainability benefits.

Indications That It’s Time to Replace Your Desiccant Air Dryers

Desiccant air dryers are essential components in industrial settings, responsible for maintaining the quality and integrity of compressed air systems by removing moisture. However, like any equipment, desiccant air dryers can deteriorate over time, leading to compromised performance and potential issues. Recognizing the signs that it’s time to replace your desiccant air dryers is crucial for ensuring efficient operation and preventing costly downtime. Here are five indicators to watch out for:

Increased Maintenance Frequency

One clear sign that your desiccant air dryers may need replacement is a sudden increase in maintenance frequency. If you find yourself constantly addressing issues such as clogged filters, valve malfunctions, or motor failures, it could indicate that the desiccant material is no longer effectively removing moisture from the compressed air. Increased maintenance requirements not only disrupt operations but also incur additional costs. Evaluating whether the frequency of maintenance has significantly risen can help determine if replacement desiccant air dryers are necessary to restore reliable performance.

Inconsistent Dew Point Levels

The dew point is a critical parameter that indicates the moisture content of compressed air. If you notice fluctuations or inconsistencies in dew point levels, it could signal that your desiccant air dryers can no longer maintain consistent moisture removal. Inconsistent dew point levels may result in moisture-related issues downstream, such as corrosion, equipment malfunction, or product contamination. Monitoring dew point levels regularly and noting deviations from the desired range can help identify when replacement desiccant air dryers are needed to ensure consistent moisture control.

Unusual Odors or Contaminants in Compressed Air

Desiccant air dryers are designed to remove moisture and contaminants such as oil, particulates, and odors from compressed air. Detecting unusual odors or contaminants in the compressed air stream may indicate that the desiccant material is saturated or degraded. Contaminated compressed air can compromise product quality, damage equipment, and pose safety risks. Conducting regular air quality tests and inspecting the compressed air for signs of contamination can help determine whether replacement desiccant air dryers are necessary to maintain clean and dry compressed air.

Decreased Productivity or Efficiency

A decline in productivity or efficiency can be a telltale sign that your desiccant air dryers are no longer performing optimally. If you notice a decrease in production output, increased energy consumption, or reduced equipment efficiency, it could be attributed to inadequate moisture control provided by the desiccant air dryers. Poor moisture control can lead to equipment downtime, product defects, and increased operating costs. Assessing changes in productivity or efficiency metrics can help identify when replacement desiccant air dryers are required to restore optimal performance.

Age of the Equipment

Lastly, the age of your desiccant air dryers can be a significant factor in determining whether replacement is necessary. Like any equipment, desiccant air dryers have a finite lifespan and may become less effective due to wear and tear, degradation of desiccant material, or technological advancements. If your desiccant air dryers are approaching or exceeding their expected lifespan, it may be prudent to consider replacement with newer, more efficient models that offer improved performance and reliability.

Partner With Pioneer Air Systems for Industry-Leading Desiccant Air Dryer Replacements

With a reputation for quality and reliability, Pioneer offers cutting-edge solutions to meet your moisture control needs effectively. Reach out today for the best replacement desiccant air dryers.