https://pioneerair.com/wp-content/uploads/2024/05/Choosing-Replacement-Desiccant-Air-Dryers-Pitfalls-to-Avoid.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/05/pioneer_air_systems_logo.png

Abstrakt Marketing2024-05-09 20:47:392026-01-16 20:43:36Choosing Replacement Desiccant Air Dryers: Pitfalls to Avoid

https://pioneerair.com/wp-content/uploads/2024/05/Choosing-Replacement-Desiccant-Air-Dryers-Pitfalls-to-Avoid.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2022/05/pioneer_air_systems_logo.png

Abstrakt Marketing2024-05-09 20:47:392026-01-16 20:43:36Choosing Replacement Desiccant Air Dryers: Pitfalls to AvoidThe Environmental Impact of Hydrogen and Nitrogen on Dry Air Systems

Hydrogen and nitrogen drying solutions have emerged as eco-friendly alternatives, offering numerous benefits in comparison to traditional drying methods. This blog will delve into the environmental impact of hydrogen and nitrogen drying solutions, shedding light on their reduced carbon footprint, energy efficiency, and overall contribution to a more sustainable future.

The Eco-Friendliness of Hydrogen and Nitrogen

Hydrogen and nitrogen, both abundant gases, have gained prominence as environmentally friendly alternatives in drying processes. Unlike conventional methods that often rely on energy-intensive processes and contribute to pollution, these gases offer a cleaner and greener approach.

Reduced Carbon Footprint

Hydrogen and nitrogen drying solutions significantly reduce carbon emissions compared to traditional methods. The combustion of hydrogen produces only water vapor, eliminating the release of harmful greenhouse gases. In contrast, fossil fuel-based drying methods emit substantial amounts of carbon dioxide, contributing to climate change.

Energy Efficiency

Hydrogen and nitrogen are inherently energy-efficient gases. The use of hydrogen as a fuel source for drying processes is gaining traction due to its high energy content. Nitrogen, when employed for inert gas drying, prevents oxidation and moisture-related damage while minimizing energy consumption. These attributes make hydrogen and nitrogen drying solutions environmentally friendly and economically viable in the long run.

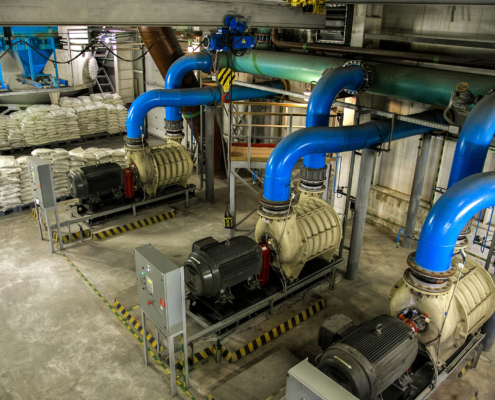

The Role of Hydrogen and Nitrogen for Dry Air Systems in Industrial Facilities

Together, hydrogen and nitrogen contribute to the optimization of dry air systems, offering a more sustainable alternative to traditional methods. Their energy efficiency and the ability to tailor drying conditions position these gases as key components in fostering a greener, more efficient future for industrial facilities. As industries increasingly prioritize eco-friendly practices, integrating hydrogen and nitrogen in dry air systems represents a pivotal step towards achieving operational excellence and environmental stewardship.

At Pioneer, we don’t just carry dry air system solutions, we also have products for breathing compressed air systems. Check out more today.

The Benefits of Dry Air Systems in Facilities

- Enhanced Equipment Longevity: Dry air systems, utilizing hydrogen and nitrogen, prevent corrosion and moisture-related damage, extending the lifespan of industrial equipment.

- Reduced Maintenance Costs: By minimizing the risk of oxidation, these systems lower maintenance expenses associated with repairing or replacing corroded components.

- Optimized Production Processes: The controlled moisture levels in industrial facilities improve manufacturing processes’ efficiency and precision.

- Environmental Sustainability: Hydrogen’s clean combustion and nitrogen’s inert properties contribute to a reduced environmental impact, aligning with eco-friendly practices.

- Energy Efficiency: Dry air systems powered by hydrogen and nitrogen offer energy-efficient drying solutions, reducing overall energy consumption in industrial settings.

Carbon Emissions

Traditional drying methods often involve the combustion of fossil fuels, releasing carbon dioxide into the atmosphere. Hydrogen, a clean-burning fuel, produces water vapor as the primary by-product, resulting in minimal carbon emissions. Nitrogen, used in inert drying processes, contributes negligibly to carbon emissions, starkly contrasting traditional methods.

Energy Usage

The efficiency of hydrogen and nitrogen drying solutions becomes evident when comparing energy consumption. Traditional methods may require higher energy inputs due to the inefficiencies associated with combustion and heat transfer. In contrast, hydrogen’s high energy density and nitrogen’s inert properties allow for more efficient drying processes, reducing overall energy requirements.

Waste Reduction

Hydrogen and nitrogen drying solutions contribute to waste reduction by minimizing the need for additional chemicals and by-products associated with traditional methods. The clean combustion of hydrogen results in water vapor, while nitrogen-inert drying eliminates the need for reactive gases, reducing waste generation and simplifying the overall process.

Ongoing Research and Innovations

The journey towards a more sustainable future doesn’t stop at the current state of hydrogen and nitrogen drying solutions. Ongoing research and development initiatives are pushing the boundaries, seeking innovations that enhance environmental friendliness.

Technological Advancements

Researchers are exploring advanced technologies to optimize hydrogen and nitrogen drying processes further. This includes developing more efficient catalysts for hydrogen combustion, enhancing nitrogen purity for inert drying, and exploring novel materials to improve overall system efficiency.

Integration With Renewable Energy

The integration of hydrogen and nitrogen drying solutions with renewable energy sources is a promising avenue. Combining these drying methods with solar or wind power can further reduce the environmental impact, creating a synergistic relationship between clean energy and sustainable industrial practices.

Smart Control Systems

The advent of smart control systems enables better monitoring and optimization of drying processes. These systems can dynamically adjust parameters based on real-time data, ensuring maximum efficiency and minimal environmental impact. This level of precision contributes to a more sustainable and resource-efficient approach.

Shaping a Sustainable Future

The advancements in hydrogen and nitrogen drying solutions underscore a paradigm shift in industrial practices, reflecting a commitment to environmental sustainability. As these technologies continue to evolve, they play a pivotal role in shaping a more sustainable future for industries worldwide.

Industry Adoption and Awareness

The increasing adoption of hydrogen and nitrogen drying solutions by various industries signals a growing awareness of the environmental impact of traditional methods. Companies are recognizing the importance of aligning their operations with sustainable practices for regulatory compliance and as a strategic investment in long-term environmental stewardship.

Regulatory Landscape

Governments and international bodies are introducing regulations to curb carbon emissions and promote sustainable practices. Hydrogen and nitrogen drying solutions align with these regulatory frameworks, positioning industries favorably in the face of evolving environmental standards. Proactively adopting these technologies reflects a commitment to staying ahead of regulatory changes and mitigating environmental impact.

Collaborative Initiatives

Collaborations between industries, research institutions, and government bodies foster a collaborative approach to sustainable technology development. By sharing knowledge, resources, and expertise, stakeholders contribute to the accelerated advancement of hydrogen and nitrogen drying solutions, driving innovation and establishing best practices.

Pioneer Air Systems: Your Source for Hydrogen and Nitrogen Drying Solutions

At Pioneer, we stand as your dedicated partner for cutting-edge hydrogen and nitrogen drying solutions. Our commitment to excellence ensures tailored, eco-friendly, and energy-efficient solutions, empowering your industrial operations for a sustainable future. Reach out to our team today to get started.